Powering the Solar Panel Bracket Industry

3-Chuck Tube Laser Cutting Machine: Powering

the Photovoltaic Bracket Industry

The Importance of Photovoltaic Brackets

Photovoltaic brackets play a crucial role in solar photovoltaic power generation systems, serving as the "skeleton" that supports, fixes, and rotates the modules. Their technical performance directly impacts the efficiency and ROI of the power station.

As countries worldwide focus on new energy industries, the demand for high-quality photovoltaic / Solar Panel brackets is on the rise.

Market Overview

The photovoltaic technology landscape is rapidly evolving, leading to reduced costs and a promising future for solar power generation. Despite a slowdown in 2020 due to the pandemic, global shipments of photovoltaic brackets are expected to reach 142.1GW in 2022.

The ACME Advantage

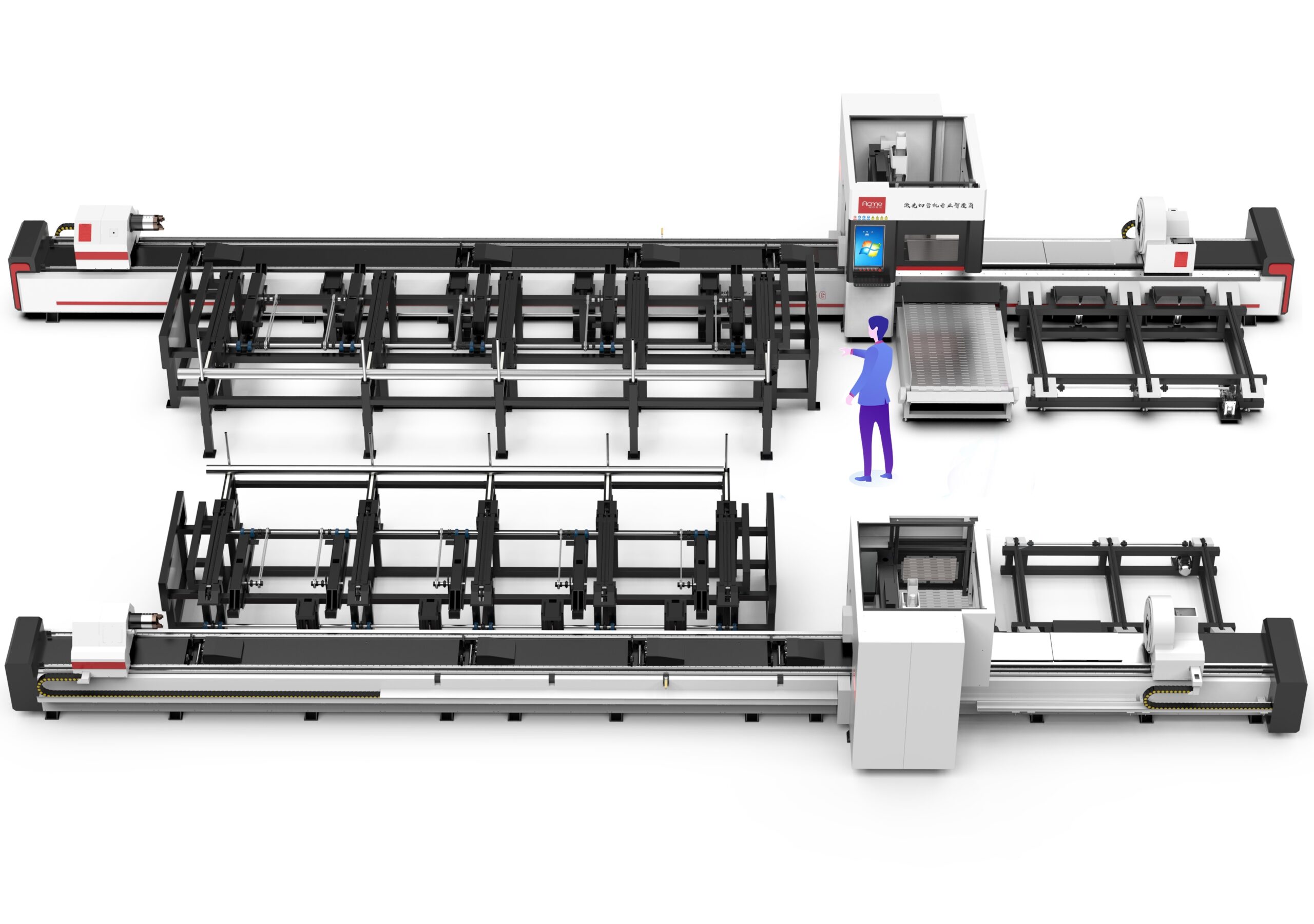

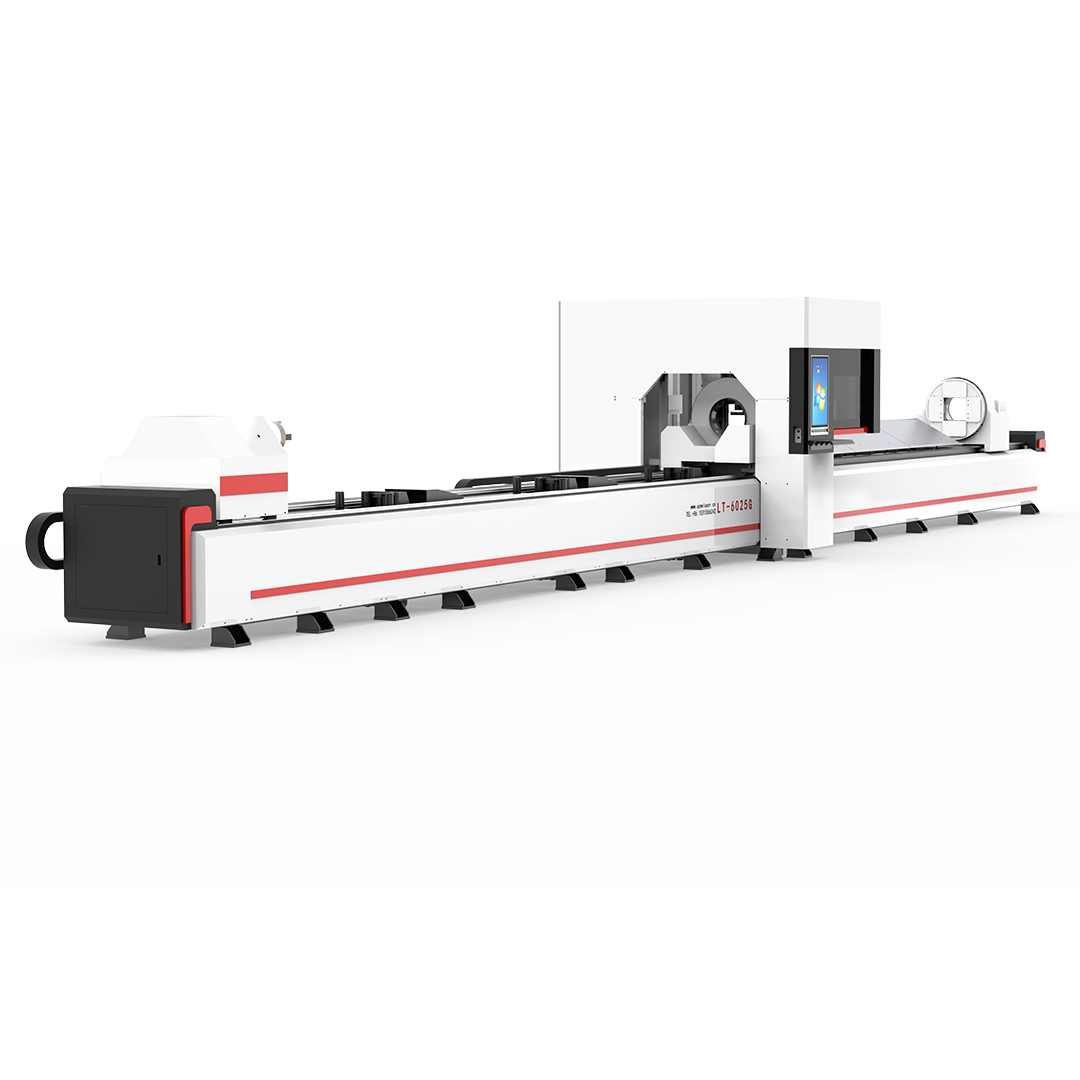

ACME's 3-chuck tube laser cutting machines are revolutionizing the photovoltaic bracket industry by overcoming the limitations of traditional metal processing methods.

Tube laser cutting machine breaks the production limitations of traditional metal processing,

upgrades the manufacturing process, and greatly improves the production efficiency. Start widely

used in this industry.

Key Features

Zero Material Waste: The three chucks work in unison, allowing the laser cutting head to move behind the middle chuck, achieving zero tailing and reducing material loss.

Automated System: With a maximum bearing tube weight of 5 tons, the machine offers automated loading and continuous cutting, enhancing work efficiency.

Versatility: Unlike most three-chuck laser machines, ACME's version can handle both large and heavy tubes.

Profile Flexibility: Capable of cutting not just standard shapes like round, square, and rectangle tubes, but also special profiles like I-beams, channel steel, and angle steel.

Precision: The strong clamping force of the three chucks minimizes fluctuation during tube rotation, ensuring high cutting accuracy.

Broad Applications

ACME's 3-chuck tube laser cutting machines are already making a significant impact in various industries, including photovoltaic brackets, fitness equipment, furniture, and automotive manufacturing. They offer high-speed, high-precision, and high efficiency tube cutting, backed by excellent product experience and after-sales service.