Elevating the Mining Equipment Industry

The Changing Landscape of Mining

The Changing Landscape of Mining

As the mining industry evolves to meet higher quality standards and environmental regulations,

the demand for advanced mining equipment has never been greater. The shift towards more

efficient, energy-saving technologies has led many manufacturers to opt for fiber laser cutting

equipment over traditional methods. This technology is not only transforming the mining sector

but also finding applications in engineering projects, large steel mills, and ports.

Key Materials in Heavy Conveying Machinery

The primary materials used in mining heavy conveying machinery include channel

steel and round pipes. These form the non-fixed parts of the machine's body and

brackets, which are often non-bolted for simplicity. The machinery typically employs

trough idlers, bottom stack rolls, and driving drums.

Common Cutting Specifications

Channel Steel (10#—20#): Thickness ranges from 3mm to 8mm.

Round Pipes (30-219): Thickness ranges from 3mm to 6mm.

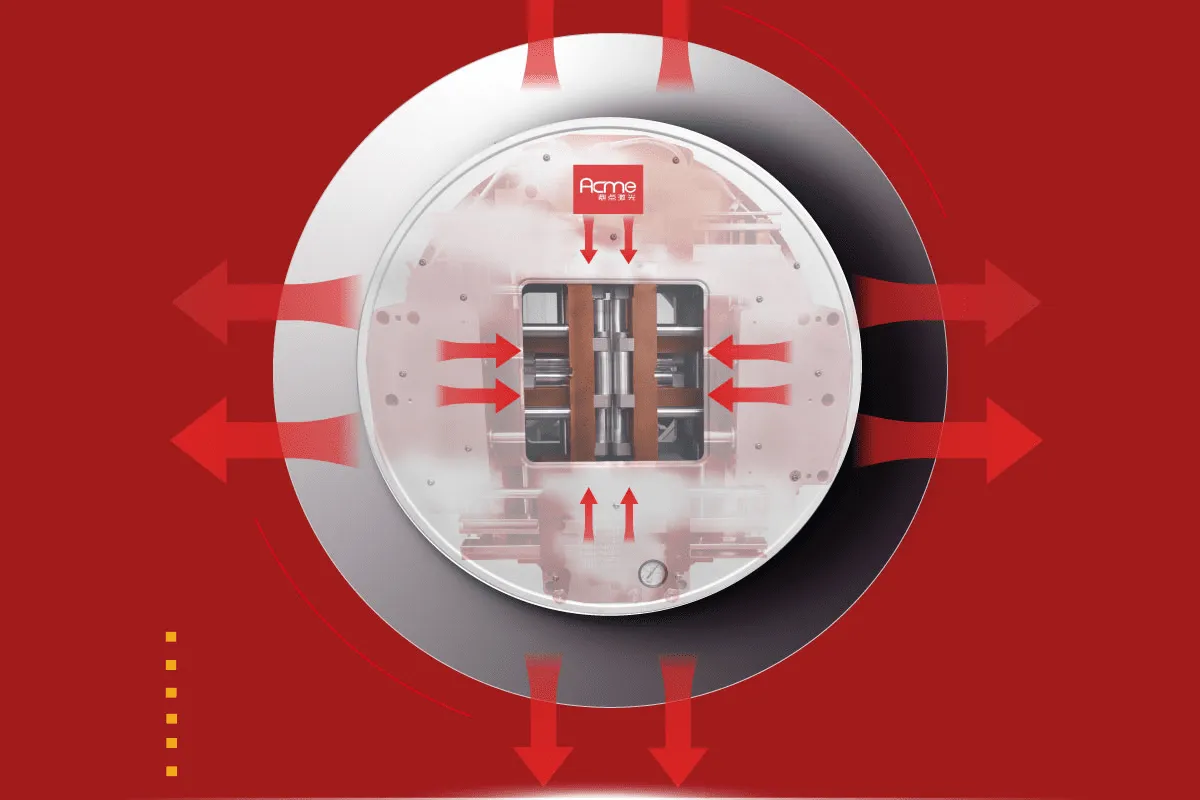

Product Advantages

Stability: High load-bearing capabilities.

Versatility: The square chuck profile allows for a wider cutting range.

Efficiency & Precision: Faster and more accurate than traditional sawing and punching

machines.