A Commitment to Green, Low-Carbon

Solutions!

Leading the Way in Sustainable Steel Structure Processing.

Leading the Way in Sustainable Steel Structure Processing.

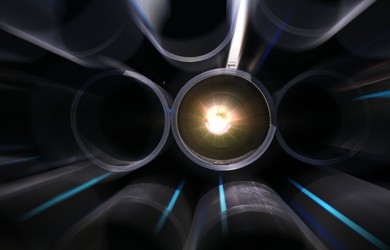

Laser technology is increasingly recognized as a green and environmentally friendly

alternative to traditional cutting methods. Its applications in steel structure

enterprises are growing due to its unparalleled advantages over old and inefficient power consuming technologies, such as CNC Plasma cutters.

Advantages of ACME Laser Machines

In line with China's focus on energy consumption control, ACME Laser is committed

to innovation in laser tube cutting machine production. Our machines not only save

manpower but also reduce energy consumption and pollution, aiding manufacturing

enterprises in their energy-saving and carbon-reducing efforts.

New Technology: Static Cutting

Launched in May 2022, our "static cutting" technology increases laser cutting speed

by 20% and reduces energy consumption by 60%. This breakthrough aligns with our

commitment to energy efficiency and low consumption, addressing long-standing

industry challenges.

Three Chucks Zero Tailing: Cost-Effective and Efficient

Our three-chuck series cutting machine minimizes waste by enabling rapid

processing of ultra-long workpieces and zero-tailing cutting. This not only improves

processing accuracy but also significantly reduces material waste and long-term

production costs.

Intelligent Processing: A Sustainable Approach

ACME Laser has developed a fully automatic loading rack that intelligently distributes

and feeds bundles of tubes. This innovation reduces labor costs, improves processing

efficiency, and shortens production cycles, making the process more

environmentally friendly and efficient.